| Characteristic: | |

|---|---|

| Availability: | |

COLOR

PRODUCT DESCRIPTION

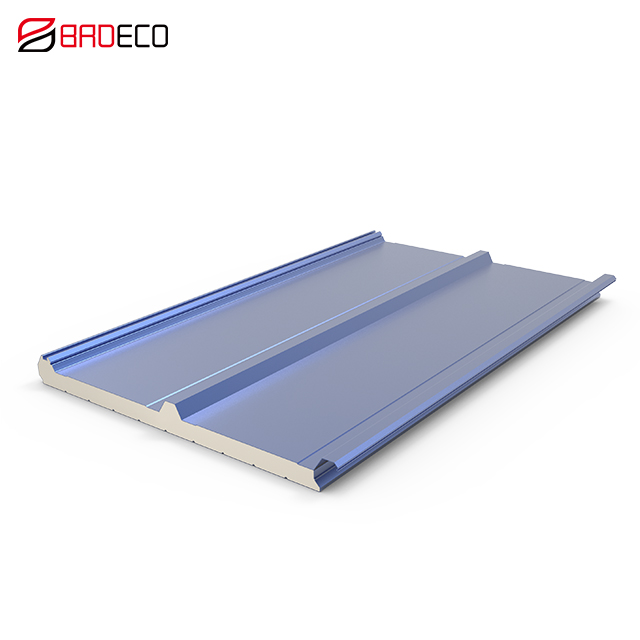

The PU Foam Metal Deck is divided into two types:

i) Three Waves of Polyurethane Composite Roof Panel

ii) Four Waves of Polyurethane Composite Roof Panel

SPECIFICATION

| PU Foam Metal Deck | Parameter Description |

| Thickness of the Steel Sheet | 0.4-0.7mm |

| Density of Core Material | 40kg/m3 |

| Standard Length | From 2 m to 10 m (with a maximum of 12 m) |

| Thickness of Core Material | 50, 60, 75, 80, 100mm (Max 200mm) |

| Standard Thickness | 50-75mm |

| Colors | Any RAL Color |

| Thermal Conductivity (W/m.k) | ≤0.023 |

| Way of Instalation | Horizontal / Vertical |

| Compressive Strength (kg/cm3) | 2.0-2.7 |

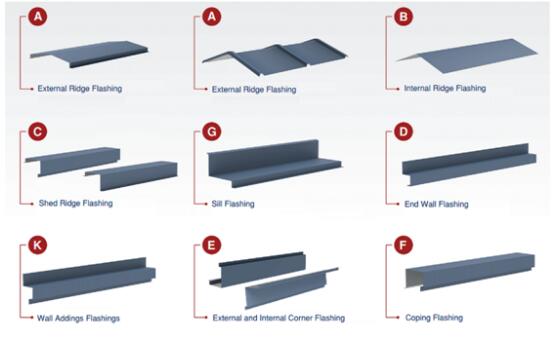

SYSTEM ACCESSORIES

Professional technical assistance is offered throughout the construction cycle, including pre- and post-production.

Reach us for additional services like as U Value/Condensation risk calculation, tailored construction detail, fire and acoustic performance advice, panel spans, fastener & roof drainage calculations, optimal lighting designs, building energy modeling, and installation training.

APPLICATION

Because of its superior insulation properties, PU (polyurethane) Metal Decks are often used in these structures for heat insulation and sound deadening purposes such as:-

Factory

Warehouse

Chemical Laboratory

Building Expansion and Renovation

Supermarket

Hospital.

INSTALLATION PROCESS

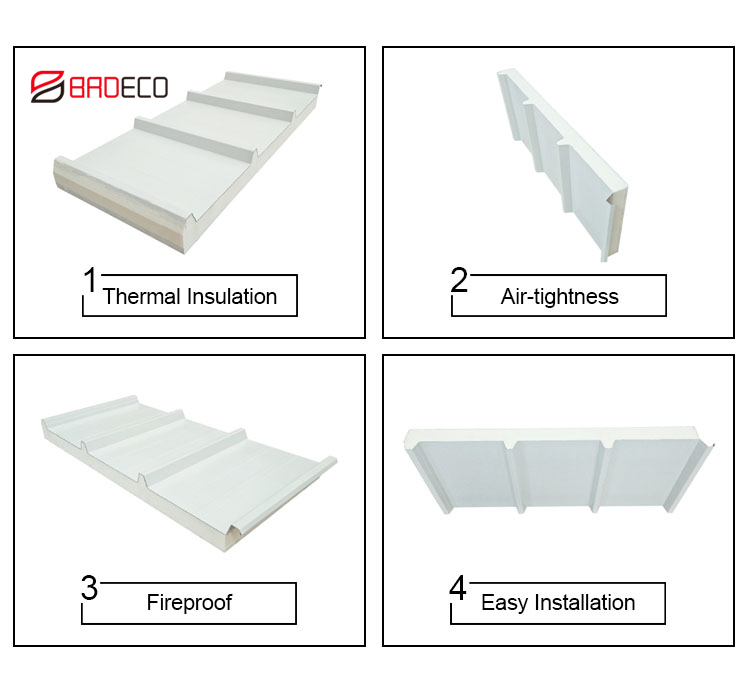

ADVANTAGES

1.Created exclusively 4 wave roof panel in China for the first time, more powerful for snow load.

2. Exclusively adopt the 3 wave roof, embedded installation, dark nail waterproof technology, easy installation, guarantee 100% hold water.

3.Adopt the 40 cm peaks, increase the surface strength, easy drainage, reducing both snow load and wind load by 170%.

4.Super flame retardation

The coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

5. Easy and quick installation

Compared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.